Circular Saw Blades

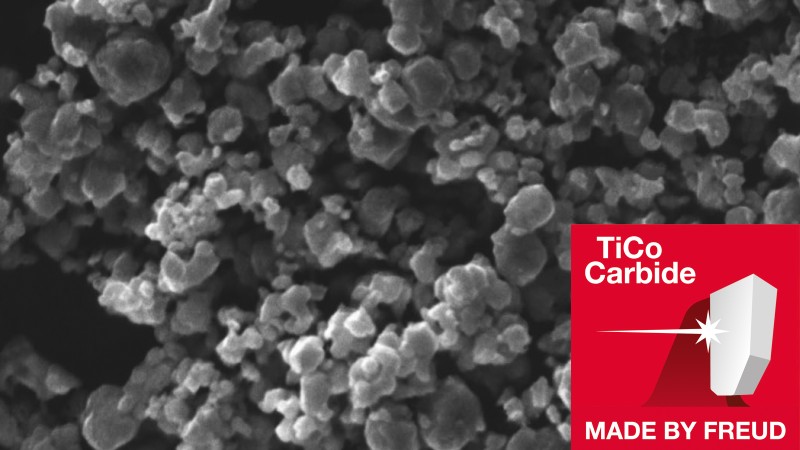

Freud is the biggest manufacturer of industrial circular saw blades in the world. At Freud we continuously invest in the finest materials and sophisticated manufacturing technologies, to produce premium circular saw blades that deliver flawless results and long-term performance. The cutting edges of freud circular saw blades are made in TiCo, a specially formulated, highly compact Titanium Cobalt Carbide, engineered and manufactured in-house in our dedicated plant in Italy.

In-house Tungsten Carbide (HW) production

In-house Tungsten Carbide (HW) production

• TiCo Carbide is a specially formulated, highly compact Titanium Cobalt Carbide, engineered and manufactured in-house by Freud.

• Special HW grades are mixed based on application needs and checked according to strict quality criteria.

• Special tooth geometries are developed for perfect cuts.

Multiple sharpenings: super square tooth design

Multiple sharpenings: super square tooth design

• Tip thickness 30% greater than standard tips.

• Up to 25 sharpenings to extend the product lifetime.

Maximum durability: tri-metal shock resistant brazing

Maximum durability: tri-metal shock resistant brazing

• Freud special tri-metal alloy consists of copper wrapped between layers of silver.

• This solution allows the Carbide tips to withstand extreme impact, for maximum durability.

Improved precision: Anti-vibration slots for the perfect finishing

Improved precision: Anti-vibration slots for the perfect finishing

• Body slots laser cut with Freud innovative technology.

• Also available with thermoplastic polyurethane filling, that considerably reduces vibration and minimizes noise.

No blade distortion: laser cut steel, tensioning and balancing

No blade distortion: laser cut steel, tensioning and balancing

• The high strength laser cut steel extends the blade durability, whereas the tensioning process guarantees maximum precision.

• An automated system balances Freud blades one by one, eliminating completely the harmful vibrations.